In our previous blog post, we mentioned that cross-merchandising is best communicated using planogram software and that cross-merchandising impacts how stock replenishment software performs its job. It's not just cross-merchandising though, the entire space planning process impacts stock replenishment.

Product space reallocations, new line introductions, cross-merchandising, etc. all impact stock replenishment. The logical conclusion is that planogram software and stock replenishment software must be integrated to make retail operations more efficient and effective.

Here are some specific issues where planogram software can assist stock replenishment software to make more efficient decisions.

1. Initial orders

Initial orders refer to the amount of stock to be ordered (Outside an automated replenishment system) to ensure that shelves appear fully stocked. Initial orders are usually placed when there's a new line introduction, significant changes in product space allocations, and new store openings.

Space planners regularly update planograms with new sales data, which changes product space allocations. New line introductions have a “space occupied” knock-on effect on existing lines. Where these changes are significant, Initial Orders must placed to optimize product/store performance.

Planogram software, like DotActiv Enterprise, considers stock at the store, stock at the distribution center, and changes in product quantity required (as a result of either product space allocation changes or new line introductions) to calculate the additional demand that will need to be met to implement the planograms successfully.

2. Slow-moving lines

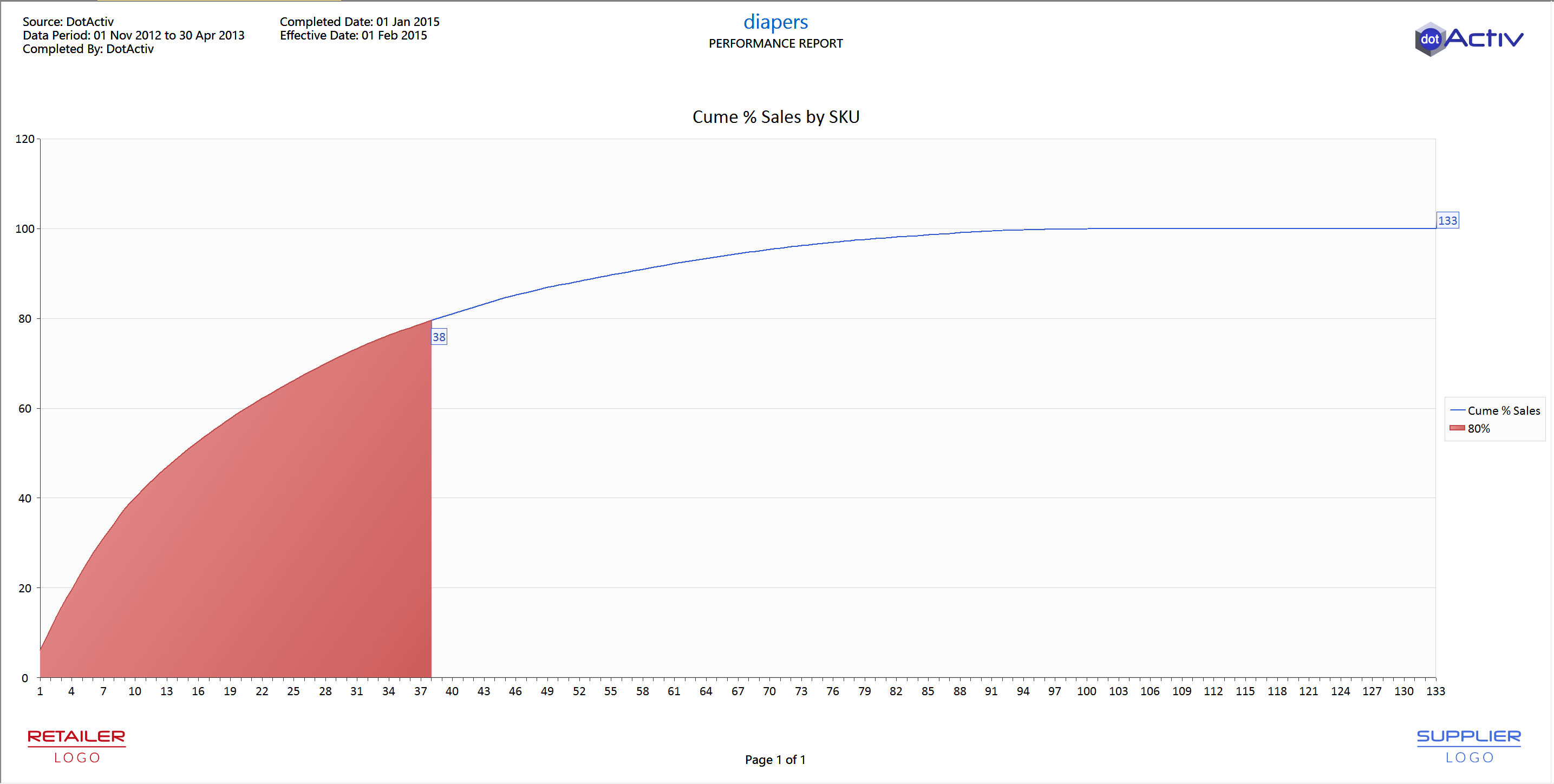

Usually, FMCG retailers get most of their revenue from 20% of their listed products. This leaves retailers with more slow-moving products than fast-moving products... The below graph shows a category that gets 80% of its sales from 38 of the 133 products.

The challenge is that 71% of the products are slow-moving, and if their minimum display quantity (based on their space allocation and product attributes) isn't considered part of the stock ordering process, then the shelves may end up appearing semi-stocked and messy.

3. Product Minimum Display Quantity

We touched on this in a point above but only in the context of ordering enough but not too much for slow-moving lines. Below we dive into the psychology, science, and result of catering for minimum display quantities in a more general context.

The psychology - Ever wanted to buy the last product on the shelf? Me neither. Shoppers naturally feel more enticed to buy when there's a minimum display of the product on the shelf.

The science - Planogram software sends "capacity" for each product in each store to stock replenishment software. This capacity is calculated as follows: Actual Facings (the number of facings the product will get for a particular store) multiplied by Minimum display depth (the minimum number of products behind each other to look good in-store). This ensures that the minimum number of units required to stock a shelf to an aesthetically pleasing level is accounted for.

The result - Store shelves always look well stocked with each product which leads to more enticing product displays for consumers, which encourages additional in-store sales.

4. Cross Merchandising

Cross-merchandising is a practical tactic that category managers use to drive additional in-store sales. They do this by including a product in a category even though it doesn't belong.

If a product is found in a second location, there will be an effect on the total amount of stock needed to implement both planograms successfully.

The decision to cross-merchandise an item cannot be anticipated by auto-replenishment. Planogram software, like DotActiv Enterprise, can provide the accurate total capacity values required to improve both the initial orders and the auto-replenishment decisions made.

Conclusion

As a retailer, both store space and stock are your biggest assets. And if managing them to perfection is your goal, you'll need to integrate the tools you use to manage them.