When discussing days of supply, a point worth considering is its value to you as a retailer. Of course, that leads to the question of what kind of value you can expect. For one, there is the value of having control of it. Failing to control it can see you paying dearly. And we are not only talking about money. It can also damage any hard-earned reputation.

Failing to control it can lead to fewer customers visiting your store because they suspect (sometimes rightfully so) that you do not have what they need when they want it. Fortunately, you can take action to curb such thinking - this is all in your control. It is now up to you to do something.

How? That’s simple. You turn to specialist software and professional services built specifically to help you manage the products you stock in-store. That leads to an improved reputation with your customers - they get what they want - while you reap the reward of increased profitability.

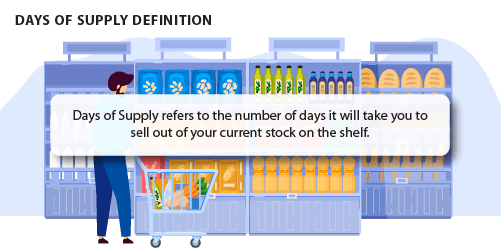

What are days of supply?

Before we explain the value of days of supply - DOS for short - we must establish and unpack it for what it is.

What do we mean when we talk about days of supply? It is straightforward to understand.

In simple terms, DOS is how many days you can expect a product to last in-store before you restock your shelf. And by the way, it is not a guesstimation or pulled out of thin air. It considers numerous factors like individual unit movement and product and fixture dimensions to give you an accurate number.

Also, various circumstances that influence it, including:

- Seasonality;

- Out-of-stock situations; and

- In-store cross-promotions.

As for its value (and importance), you cannot take it for granted. Why? As mentioned, DOS is a measure to know when to replenish your store shelf. But it is more than that. By being aware of it, you'll know how often your stock turns over, which impacts your inventory plans.

So what happens if you have no control? Will it be that bad? The short answer is yes. Unequivocally.

By not having control of your days of supply, you can find your store/s running out of stock. Why? Because without data, you won't know how quickly your products sell out. You can guess, yes, but you won't have an accurate understanding.

For example, one product might be a fast mover while another is slow to sell out. Before you know it, you could have gaps on all your shelves. On the other hand, how will you know how much to order or reorder to meet consumer demand?

You could even find yourself overcompensating and running the risk of stocking your store/s with too much of the wrong product. And that will cost you money that you should not need to spend.

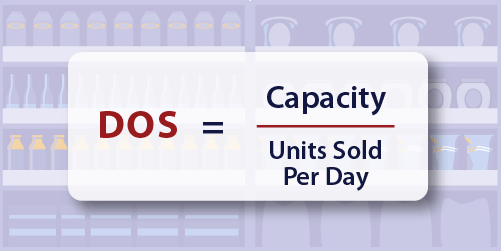

Days of supply calculation explained

Just as its definition, the days of supply calculation is easy to understand.

Here it is:

If you were to expand on that, it would be to explain that capacity refers to the total count of units of a product you have on your planogram.

Meanwhile, units sold per day is self-explanatory - it refers to daily movement, which adds to your weekly movement.

As for the formula, it allows you to measure three specific aspects of your retail business, namely:

- The days of supply for each product;

- The average days of supply for your shelf and gondolas; and

- The overall days of supply for your store.

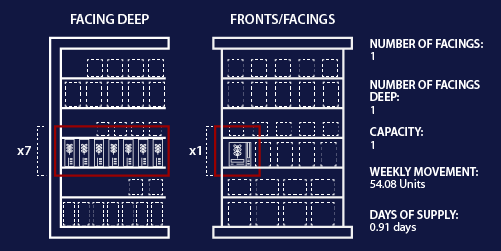

So what does that look like in a practical example? Here you go:

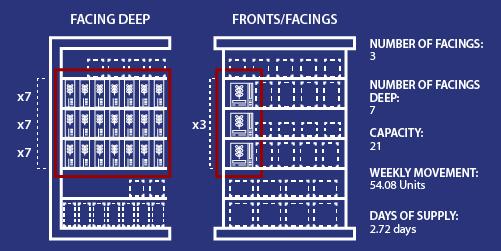

In the below image, Cereal Brand A has a product on the shelf. The weekly movement for this product is 54.08 units. It also has a DOS of 0.91 days. Let us say it has one facing and the shelf capacity is seven. That means you can expect the product to sell 54 units per week. You will also have enough stock on the shelf to last less than a day.

Should you increase the number of facings, and thus the capacity, your DOS will increase too. If you wanted to increase your facings to three, capacity would jump to 21, and your DOS would increase to 2.72, as seen in the image below.

That means you do not need to restock daily to meet demand. Of course, you must be careful of overstocking because that can turn an aesthetically pleasing and easy-to-shop shelf (and aisle) into a confusing mess.

It also leads to one last question: how will you know if your days of supply are accurate?

Days of supply rely on a few specific aspects. Without the accuracy of the below, you will skew DOS, which affects everything else.

These aspects include:

- Capacity: This includes your product and fixture dimensions. With such information, you know how many products fit on your shelf without being over-congested.

- Number of Units Sold: Since the formula for DOS relies on how many units you sell per day, it goes without saying that you need to know the quantity of the items that sell. Again, without this, it will skew your data, which can lead to a shelf that is over capacity.

- Period: As with any analysis work you want to complete, you need a specific period. During this period, you can work out how many units you sell.

When building a planogram, you must align the DOS of your products as much as possible. Averaging it out means all products can sell out at the same rate. That reduces the possibility of unnecessary gaps appearing on your shelf and means your merchandisers (or whoever you assign shelf replenishment duties to) will not need to restock your shelves too often.

How can DotActiv help ensure you manage your days of supply?

1. Managing days of supply

Luckily for you (and our consultants), DotActiv software calculates days of supply automatically. No time is wasted manually calculating each product’s DOS. With the DotActiv software, you can access your DOS using the floating status or the planogram analyzer features.

The floating status is useful when managing the days of supply per product.

If your aim is to manage the days of supply of the entire planogram, the planogram analyzer will be a better option.

By utilizing our software features, you can see how many days it will take for a product to sell out before you need to replenish your shelves. You can determine whether the products on your planogram will sell out at the targeted rate for your category or whether it’s time to look at the merchandising strategy.

Managing days of supply is about streamlining your operations - it’s time-saving and labor-saving. But to properly action days of supply, we need two-way database integration.

With two-way database integration, we avoid errors when importing data and save time with an automated system. Stores can track the rate at which they need to replenish shelves, minimizing dormant and unwanted stock.

2. Maintain better stock control

The DotActiv software features allow you to know the minimums and maximums and communicate this to your stakeholders. Determining the number of days it will take for your products to run out on shelves has made tracking your fast movers and your slow movers an effortless process.

We have already discussed the floating status and planogram analyzer and how these features will benefit you when building planograms. However, there is one last feature when looking at days of supply. Do not forget to use it - especially if you want to avoid making mistakes.

The Highlights function will show you exactly where the planogram needs a little TLC.

By setting up a spectrum highlight where the lowest 10% of DOS is in blue, and the highest 10% of DOS is in red, you can see which product’s days of supply are too high.

Using all three of these features together will ensure best practice. You will avoid giving products with a high DOS more space on the planogram and placing all the products with a low DOS on one drop - causing a foot traffic nightmare.

After you have used your floating status and planogram analyzer, and analyzed your highlights, you can determine whether your DOS meets your predetermined KPIs.

3. Choosing a specialist service

We already know that managing days of supply is vital to building data-driven planograms that will deliver the goods, but which services does DotActiv provide that can facilitate planogram development?

At DotActiv, we have a range of services to suit your category management needs and trained category specialists to meet them. If managing days of supply is on your priority list, our space planning and category planning services will help you reach your goals.

Along with our category specialists, you will decide which DOS makes the most sense for your category, and they will make it happen.

Depending on your category management needs, we will require information from you to provide you with our services, including but not limited to:

- Product information (images, dimensions, and descriptions)

- Store information (store size and LSM)

- Fixture information (fixture types and dimensions)

- Point of sale data (sales and units)

But is it worth it? The short answer is yes.

Our category specialists are problem-solvers who offer objective insights and action strategies. With our category management services, you will receive data-driven and performance-enhancing planograms that will increase your ROI and drive sales.

Often we see overstocking and understocking, poor demand forecasting, and an inefficient supply chain. With a robust category management system, you will balance DOS effectively and understand your customer demand, inventory levels, and supply chain. In return, operations will streamline, customers will be happy, and you will gain a competitive advantage.

Balancing days of supply is not only about looking at numbers. It requires a proactive and continuous approach to category management. You must understand the category you are working with and its role within your store to determine the optimal days of supply.

For example, because we buy food more often than cosmetics, we can expect the days of supply for cosmetics to be much higher, but this does not indicate that cosmetic products are poor sellers. It would be perfectly acceptable for your cosmetics to have a higher DOS. On the other hand, perishable products like food would require a lower DOS.

Conclusion

Understanding days of supply and how to use it correctly can help you set up your retail business for success. And it's not just in the short-term either. It's just as relevant to understand no matter where you are in your retail journey.

Are you looking for advice or need a category management solution that can help you maximise your sales potential while also pleasing your customers simultaneously? Book your complimentary consultation with a DotActiv expert today and we'll show you how you can achieve that and more. You can also browse through our various software editions and services on our online store.