Let's be real - facing a backorder isn't a scenario you want to face. Instead of telling customers a product is on backorder because it's out of stock, you want to meet the demand on the spot. Make them happy and encourage them to return. However, it happens. Fortunately, there are actions you can take and software and services you can use to prevent it.

But why does it happen? We'll touch on that in this article. For now, it's worth mentioning that there are multiple reasons. One is that it's the fault of the supply chain. It breaks down, and you can’t always control that. It can also be due to a mistake by you, the retailer. Did you anticipate demand and order enough stock?

Of course, this isn't about pointing fingers. It's about understanding what it is, why it happens, and providing a much-needed solution. In this case, it's a preventative measure in the form of specialist category management software, which you can use to ensure you can anticipate and avoid it altogether. Or better yet, an unrivaled category management service that simplifies the process so you can focus your time on the critical aspects of your retail business.

What are backorders?

Before we unpack why we believe backorders are worse than out-of-stocks, it's critical to understand what we mean when we talk about them.

According to Red Stag Fulfillment's Jake Rheude, backorders are “items that are out-of-stock but will be back in stock … soon”. He adds: “When a SKU is ‘on backorder’ that means that you are pre-ordering a product that is temporarily unavailable.” Below is another take on backorders.

That points to the fact that it's a mistake that you can attribute to your business (if you are a retailer) or your suppliers. You haven't predicted the demand for a product, and there is no available stock, meaning your supplier needs to reorder it from their manufacturer or global head office.

Of course, it's a little more complicated than that since the whole process can also involve worldwide supply and demand and different markets. You only need to consider the COVID-19 pandemic, which significantly impacted the supply chain. You could even argue that we're still seeing the after-effects.

Logistical issues

If you were to look at it from your supplier's perspective, it could be because of a logistical problem. For example, a wholesaler requests its supplier to deliver placed orders to all stores instead of its distribution center. That might not be possible because the supplier's transporting capacity limits them.

It's not a good excuse, to be fair. However, the result is a break in the supply chain because the supplier can fulfill the placed orders.

Economic climate

On the other hand, your supplier might secure orders from you and begin manufacturing but finds out that they can't meet the request. Then there is the economic climate to consider.

One of your suppliers might require Forex to purchase raw materials before beginning production. If the economy isn't performing, interest rates might be high, which affects the exchange rate which, in turn, creates shortages for the Forex on that market. Again, your supplier could struggle to deliver orders timeously.

Of course, we do need to reiterate that this isn’t only the responsibility of your supplier to get right. It’s also your responsibility as a retailer to ensure you don’t face backorders unnecessarily.

Is facing a backorder worse than facing an out-of-stock situation?

Facing a backorder isn't ideal. That much is certain. However, is it worse than an out-of-stock? That's debatable. Let's consider out-of-stocks for further clarity.

Shopify defines an out-of-stock as "the unavailability of specific items or products at the point of purchase when the customer is ready to buy".

They also quote Retail Dive, which found that stockouts cost retailers an estimated $ 1 trillion in sales. That was in 2018 from a study conducted by IHL Group, a global research and advisory firm for retail and hospitality industries.

Now let's compare that to facing a backorder. Do you lose sales? Technically, yes, because you can't sell the item your customer wants when they want it. Can you frustrate your customers? Undoubtedly. However, there is a caveat - your customers can still order the item.

Let us explain.

When running a promotion, it's possible that you could face an out-of-stock scenario. That’s especially true if the special you're running draws more attention than you could have anticipated, like a 30% discount on a Smeg stove, as an example.

In this instance, while the promotion was due to last four weeks, demand was so high that within the first two weeks, the retailer had no more stock. So, when customers came in looking for the product, a plan had to be made.

It involved taking customer details, getting someone from the retailer to call them and update them on what was happening, and then supplying them with the product as soon as possible. It took two days. A week later, the retailer’s online marketing team received an email from that client praising the effort to help them get what they wanted.

If the customer is a little patient and willing to give you time to make a plan, it’s the perfect opportunity to deliver outstanding customer service and show them that they are not just a number.

Of course, the above is just one example, and it doesn’t always happen that way. You might do the same thing for another customer who doesn’t thank you. That's the nature of customer service.

Having items on backorder also means you don't need to carry a large amount of stock at all times. If the customer knows this, it's easier to sell this scenario. When you get enough orders, you can fulfill them all at once.

Conversely, there are disadvantages, which include increased canceled orders, more complexity around payment, and not knowing if a customer will purchase the item they ordered. On the last issue, you could argue that upfront payments can help you avoid this.

All of this points to one thing - while it’s not necessarily worse than an out-of-stock situation, it’s still necessary to prevent it. That’s where specialist software and unrivaled services can play a role.

How can DotActiv help you prevent placing items on backorder?

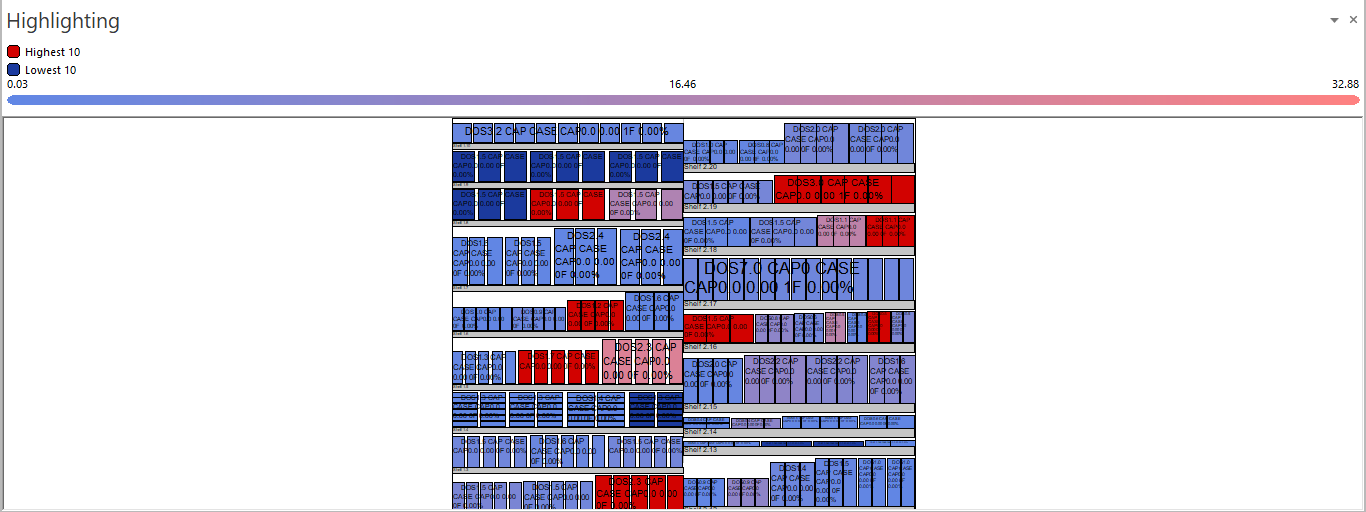

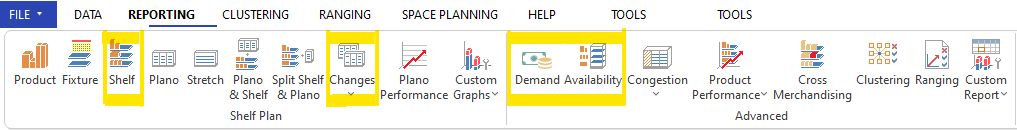

At DotActiv, our software provides a Highlights function and reporting feature to help you prevent placing items on backorder.

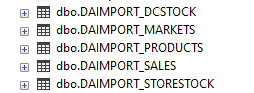

For these features to work, we must complete data integration by receiving all sales-related data from the client. We use this to build data-driven planograms that allow for the correct space allocation to each product based on its sales and unit movement.

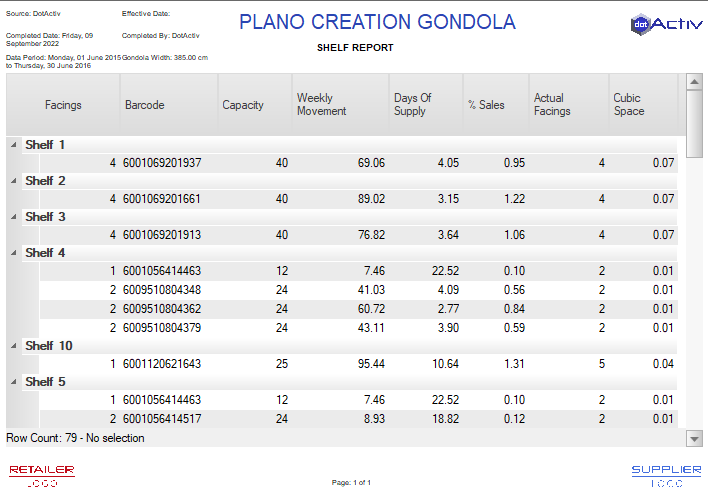

Thus, we can forecast the rate at which a product will be out of stock using the highlight function to filter by days of supply (DOS). Days of Supply refers to the number of days a product is on the shelf before you need to replenish it. We calculate DOS by the capacity/units sold.

Doing this in advance helps prevent backorders, ensures that you order your stock on time and that your shelves are filled in time before it looks empty.

Furthermore, analyzing reports contributes to making an informed decision. Reports include (but are not limited to):

- Shelf reports hold product information on a shelf such as facings, product description, weekly movement, DOS, and capacity.

- The Changes report provides insight into the improvements to your DOS and stock quantities by comparing the current and proposed planogram.

- The Availability report summarizes the quantity of stock available per store based on a specific category, thus, offering forecasting and replenishment benefits.

- Demand reports (Also known as Additional Demand, ADDM) calculate the financial impact of making any changes to your ranges or planograms.

1. Have a robust replenishment engine

Using highlights and reports (as mentioned above) containing information about the days of supply data empowers you to have more control over your stock because you can anticipate when it runs out and ensure you purchase the correct amount of stock beforehand. It makes the shelf replenishment cycle easier to manage, resulting in reduced out of stocks, optimized stock rotation, and increased inventory control.

It's beneficial as you'll know how quickly your products sell out so you can order stock appropriately. It also allows you to monitor which products you should order less stock of so you can replace them with fast-selling products (opportunity gaps).

So how does DotActiv software feed the replenishment engine?

DotActiv sends all the necessary documentation to the client.

It includes information on the following:

- Data integration process steps,

- Data Feeds document; and

- Staging Table documentation (containing sales and product information).

This data is integrated into our software monthly with all the updated data, as shown below.

Thus, when developing planograms, you have a visual representation of what your customers will see when they walk into your stores. It influences purchasing decisions, increases sales, and contributes to efficient stock replenishment.

If this all sounds overwhelming, that’s okay. There is our Planogram Development service to fall back on. Integrating DotActiv software with your system makes the work easier for everyone. When we combine the expertise of our professional category and space planners, we can ensure you meet your business goals.

Consider this. You get access to the same powerful software backed by our unrivaled service that includes access to professionals with deep technical and industry expertise who follow a well-documented process that aims to deliver results.

2. Plan and manage your stock better

Building planograms based on factual data allows you to merchandise your products and brands with great accuracy. Data-driven planograms help ensure efficiency when moving stock to shelves and, finally, from shelves into your customer’s shopping baskets.

By importing data into your planograms, various data fields will be available and empower you to identify growth opportunities and control certain variables.

In this instance, significant data fields are Sales, Days of Supply (DOS), Actual Facings, and Weekly Movement. Planograms must be data-driven to account for consumer demand and to balance the DOS.

As part of DOS, it also includes using other highlight functions such as:

- A Standard highlight (which shows all products with the same value of a specific field in the same color) shows the product grouping. The color legend helps you to see the placement of each grouping (i.e sub-category, segment, etc).

- The Spectrum highlights show the range of a specific numeric field across products using the range color between two extremes. This often is set against sales going from blue to red, which shows hotspots on your planogram/floor plan where sales are far higher than in other areas.

- An Uncommon highlight highlights products sitting in multiple different spots on the planogram. This could be useful for you just to be aware of as you build your planogram.

If you’d rather turn let DotActiv look after the above, our Planogram Development service can help you. By investing in this service, you can receive the same benefits as if you were completing the work yourself. However, we’d argue that the benefits are greater since you’re liaising with professionals well-versed in the software and how best to utilize it.

3. Consider increased collaboration with your suppliers

If you’re unsure of using DotActiv software, we also facilitate the category management process between yourself and your suppliers. It can include various levels of collaboration, funding, and participation to help you achieve your intended goals.

This service involves the following:

- Working on consumer decision trees;

- Optimizing ranges;

- Developing clusters;

- Building planograms;

- Data sharing; and

- Creating category flows and adjacencies.

If you’re familiar with DotActiv’s category management services, you may notice that the above aligns closely with that. That’s not a mistake - this service mirrors what we offer.

There are, of course, prerequisites. For example, DotActiv would fill the role of delivering on behalf of your supplier where they might not have the capacity to do so. That makes us an independent third party, acting in the best interests of the category and its performance. We’ll ensure the suggestions made by your suppliers are appropriate, insightful, and according to the level of collaboration you agreed to.

When working with you, we need to determine the level of collaboration with your supplier for each category management component. Once understood, we can define the collaboration process, roles, and responsibilities so everyone knows what to do. It might appear controlling, but if you dig deeper, it's necessary since it provides clarity. And clarity leads to increased performance.

Conclusion

The importance of preventing backorders from happening can’t be stated enough. Of course, in some instances, it’s unavoidable. However, in others, it’s entirely up to you to control it. When you can, it places you in a situation where you can consistently meet consumer demand.

Specialist software and professional services such as those offered by DotActiv make your life easier. It means you can focus on the critical aspects of your business while you let the experts, who use tried-and-tested methodologies, deliver the results you want.

Are you looking for a category management solution that’ll empower you to build space-aware data-driven product layouts that reflect your merchandising strategies and help you avoid stockouts? Or perhaps you need category management services that'll deliver such planograms to you, to perfection, every time. It all starts with a meeting.

Book a meeting with a DotActiv expert here today and we’ll provide expert advice tailored to your unique circumstances.