INVENTORY MANAGEMENT

Inventory management is any practice undertaken to handle your inventory. Your inventory or stock are those items that your business holds with the intention of selling.

Effective inventory management means ensuring you have the right inventory (and the right amount) at the right place and price.

TABLE OF CONTENTS

WHAT IS INVENTORY MANAGEMENT?

In simple terms, inventory management is any practice you would undertake to handle your inventory. Your inventory is your stock - those items that your business holds with the intention of selling.

Effective inventory management means ensuring you have the correct inventory (and the right amount) at the right place and price.

WHY IS INVENTORY MANAGEMENT SO IMPORTANT?

While inventory management might not be the most exciting aspect of running a business, you cannot underestimate its importance. Why? Simply put, it can make or break your business.

If you don’t believe that, then here are a few reasons to persuade you otherwise:

In stocking the right amount of products at the right time and price, you’ll have customers returning.

INVENTORY MANAGEMENT TECHNIQUES TO CONSIDER

Every business is different. That means when it comes to choosing which inventory management technique to follow, you won’t necessarily have the same as the business next to you. But that’s okay - as Andrew Dennis notes in an article for Shopify, inventory management is highly customisable.

Within the piece, he touches on a variety of techniques to consider. All of them will not only improve your inventory management but also your cash flow.

A few inventory management techniques to consider include:

DROPSHIPPING

A supply chain management method in which a retailer transfers customer orders and shipment details to the manufacturer, wholesaler or even another retailer. It is instead of keeping the goods in stock.

FIRST-IN, FIRST-OUT

Shortened as FIFO, it means that your oldest stock is sold first rather than your newest stock. While this method works best for perishable products, it can work just as well for non-perishable products.

Just to note, your inventory value ties in here since FIFO, along with others, including Last-in, First Out (LIFO), is a common valuation method.

DEMAND FORECASTING

Otherwise known as accurate forecasting, demand forecasting refers to the ability to predict customer demand. While it’s not the easiest technique to master, it’s worth considering since it can create repeat customers.

There is also the ABC analysis which is an inventory categorisation method. It is essentially a technique in which you divide your items into three categories which rank from your most valuable items (A) down to your least valuable items (C). It is because not all inventories are of equal value.

As Joffrey Collignon and Joannes Vermorel point out, this method “aims to draw managers’ attention on the critical few (A-items) and not on the trivial many (C-items)”. It’s also referred to as selective inventory control.

DAYS OF SUPPLY

WHAT IS DAYS OF SUPPLY?

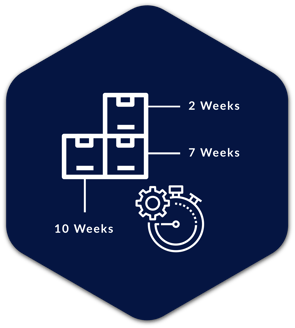

Days of Supply, or DOS as it is commonly known, is defined as “the number of days a product will be on your shelf before replenishment is necessary”.

You can calculate it when you divide your capacity by the units sold per day.

FACTORS THAT INFLUENCE YOUR DAYS OF SUPPLY

Understanding how quickly (or slowly) the stock on your shelves decreases is crucial if you want to please your customers. As you’ll have read above, it can make or break your business.

That's why it's crucial to understand the factors that can influence your days of supply. With these factors in mind, you’ll have a better chance of staying in line with the demands of your customers. That means you’ll also be able to plan better.

These factors include, but are not limited to:

Your out of stocks will influence your days of supply (DOS) since it works on how many units have moved within a certain time frame.

Just to note, whenever you stock your gondola, you must ensure that the days of supply for each of your products are as close as possible to the overall DOS of your gondola.

In cross-promoting an item across two different areas, you’re enticing your customers to buy more. The result is a lower days of supply (DOS) for those products.

That said, you do need to be careful since cross-promotion can lead to an inflated idea of how well a product is selling.

Regardless of the products you stock, you’ll only sell specific items over a period as denoted by calendar seasons (winter or summer) or for commercial reasons (Christmas or Easter). Unplanned events can also count here.

DAYS OF SUPPLY CAN IMPROVE YOUR RETAIL OPERATIONS

While various factors influence your days of supply, they can also help to improve your retail operations.

How? It all comes down to what is known as space elastic demand. It is the increase or decrease in the rate of sales, which arises because of a change in the space allocation for a product.

Now, imagine if you have two gondolas, and you merchandise your inventory differently for both. You merchandise the first consistently so that the products decrease equally on the shelf. Meanwhile, you merchandise the second so that the DOS for each product is inconsistent.

While the first will be easy to restock, the second will be a nightmare. It’s because each product will be selling out at different times, meaning that your shelf will have many gaps.

Safety stock, also known as buffer stock, can help you out here. It’s how much extra stock you should hold to ensure you don’t run out of stock. It considers supply and demand fluctuations.

“When DOS is extended beyond the shelf by including stock held at stores and distribution centres, the DOS calculation can be particularly helpful for overall replenishment.”

It’s also worth remembering: in-store experience and customer satisfaction need to be at the top of the list for any store manager. A partially empty shelf means that it’s not. And the last thing you’d want to see as a manager (or even as a customer) are staff members running back and forth in an attempt to restock empty shelves.

INVENTORY REPLENISHMENT

WHAT IS INVENTORY REPLENISHMENT?

Inventory replenishment is “the movement of inventory from upstream or reserve product storage locations to downstream or primary storage, picking and shipment locations”.

And it’s purpose is to “keep inventory flowing through the supply chain by maintaining efficient order and line item fill rates”.

HOW DOTACTIV DRIVES INVENTORY REPLENISHMENT

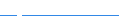

Each time a new planogram is imported into DotActiv, the causal data - facings, capacity, minimum display quantity and so on - is written to the database. Following that, we export the data to a staging table, which can be picked up and used by inventory replenishment systems.

From there, we transfer the data to the replenishment engine, which will, in turn, order the required stock based on the causal data.

How does this happen, and what specific space planning feature makes this information exchange possible? The short answer is that there isn’t a specific feature. Instead, it comes down to a combination of features within our Enterprise solution. That is because it is based on details that are within each planogram, which are linked to clusters.

While this integration doesn’t take distribution channels (DC) into account from DotActiv’s side, the replenishment engines look at what stock is in the DC’s before making the final order from suppliers.

That also means that this approach to inventory replenishment takes the supply chain into consideration. When a product is delisted, it will remain on your shelf until the stock has been depleted from the DC’s and there is minimal stock in your stores.

Why is this approach better for listing and delisting products?

Here are three reasons:

- Your product lifestyles are managed from start to finish;

- Your products can be deranged / removed from the shelf;

- Your products can't be sold out of the shop.

THE LINK BETWEEN INVENTORY REPLENISHMENT AND SPACE PLANNING

Did you know that a simple increase in the facing of a single product can impact all of your stores? The same can be said if you decrease your facings. And this will all have an impact on your replenishment model.

That is why it’s so important to manage the space allocation of your products. It’s also the basis for any argument that there is a concrete link between inventory replenishment and space planning.

To manage your space correctly, you need to know the stock and financial implications for your stores. DotActiv’s ADDM report plays an important role here.

ADDM refers to additional demand and the report “helps to estimate what the minimum required stock on shelf per SKU should be, and how many case packs should be ordered to fill that requirement”.

Don’t forget the role that space planning and inventory plays in clustered environments where a single planogram can be applied to a few hundred stores. Making changes, however small, can also have a massive impact.

THE ROLE OF SPACE PLANNERS IN INVENTORY REPLENISHMENT

While both retailers and suppliers play a role in ensuring that the inventory replenishment process runs smoothly, they are not the only important ones. Your space planners are just as crucial to the process.

Space planners must gather all relevant information to build data-driven planograms in line with the performances of your stores. You can then use the data from these planograms to ensure that your retail business has the correct inventory.

And accuracy is vital here. If it’s not accurate, there will be redundant stock sitting in one (or more) of your stores while another of your stores will run out of stock.

The result will be obvious: a loss in overall sales. But more than that, if it happens regularly, it’ll also mean that your customers will come to expect that you don’t stock certain products anymore.

ASSORTMENT, INVENTORY AND SPACE PLANNING

YOUR ASSORTMENT PLAN

Assortment planning - the “process of selecting the collection of products which will be on offer in particular areas (localisation) and specified periods of time (seasonality)” - entails the evaluation of your product attributes.

This is to address the preferences and needs of your customers. As for why it’s so important, it’s simple: in ensuring shopper satisfaction, as retailers, you can increase the financial performance of your stores. Of course, your assortment variety does increase the cost of your inventory.

YOUR INVENTORY PLAN

Selecting your collection of products is important. However, it won’t mean much if you select the wrong amount or even select them at the wrong time. It’s now up to you to figure out how much of each product you’ll need at any given time.

In having an inventory plan, you’ll not have to worry about overstocking. An effective inventory plan will indicate “when demand for a specific stock will increase”.

YOUR SPACE PLAN

When it comes to your space plan, there are two separate functions to consider:

- Macro space planning; and

- Micro space planning.

Macro space planning is essentially floor planning, and with it, you can determine both the space allocation and positioning of each product category within your store. After all, the more merchandise your customers are exposed to, the more they tend to buy.

On the other hand, micro space planning, otherwise known as shelf planning, determines the optimal positioning and space planning for each product.

That includes each subcategory as well as each brand within any given category.

THE BOND BETWEEN ASSORTMENT, INVENTORY, AND SPACE PLANNING

Whether you’re focusing on your assortment plan, your inventory plan, or even on the different aspects of your space plan, one thing is common throughout - data. More specifically, it’s the use of data.

When you don't share data between these three functions, your efforts become inefficient. More than that, your efforts become pointless. How can you know how much stock to order if you don’t understand how much space is available for each product? Only data can help you here.

Your inventory planning also impacts your planogram. When you add a product to an assortment, it gets ordered. Likewise, when you remove a product from your assortment, but you still have stock, the product will remain on the planogram.

INVENTORY PLANNING

WHAT IS INVENTORY PLANNING?

Inventory planning is fairly simple to understand.

It’s essentially defined as the “process of determining the optimal quantity and timing of inventory for the purpose of aligning it with sales and product capacity”. It also has a direct impact on your cash flow and profit margins.

In short, it’s about taking all factors into account so that you can hold just enough stock (buffer stock) so that you don’t run out and displease your customers.

FOUR SIGNS YOUR INVENTORY PLANNING NEEDS WORK

1. YOU DON’T HAVE EXTRA STORAGE SPACE

While it’s not necessarily a bad thing that you place large orders, you always need to be aware of the amount of space you have available to you before you do. When is it a good thing? When it puts your business in a position to make more margin.

Whenever you do decide to place a large order, make sure you understand more than just how much space you have.

You also need to consider the following:

- How long it will take to sell the stock;

- Where the stock will sell best; and

- When your stock expires.

2. YOUR INVENTORY LEVELS ARE RISING

How do you know when your assortment plan has gone wrong? One way of knowing is when you look at your shelf and realise you have stock that has been sitting there for far longer than expected.

A rising inventory level can also take much-needed space away from the stock that deserves it. In an effort to get rid of it, you might be forced to offer discounts. Or even worse, throw the stock away.

When reviewing your inventory, be mindful of your stock to sales ratio and be careful it doesn’t rise too far. If it does, your sales ratio needs to increase too.

3. YOUR INVENTORY MANAGEMENT IS NOT DATA-DRIVEN

If you want to ensure that your inventory planning is as efficient as possible, you must ensure that it’s not done in isolation. That means it needs to be data-driven. It also needs to be integrated.

The reason is simple: assortment planning, planograms and other category management functions are dependent on inventory planning and vice versa. This interdependency means there also needs to be a data exchange between the functions.

With your inventory management system being data-driven, you’ll be placed to offer the right product at the right place and at the right price. And you’ll have enough stock too.

4. YOU’RE EXPERIENCING OUT OF STOCKS MORE OFTEN THAN NOT

If you are finding that your store is running out of stock more often than not, you need to discover why as quickly as possible. One reason is that your inventory management capability is not as strong or as sturdy as you might have initially thought.

A sturdy inventory plan, as stated above, allows you to avoid overstocking. More than that, it anticipates how much stock you need so that you never run out.

INVENTORY CONTROL

WHAT IS INVENTORY CONTROL?

Inventory control, also known as stock control, is the process of maintaining an appropriate amount of stock so that a business can both meet customer demand and keep any unnecessary costs to a minimum.

To get this right, you need to have a robust system that can help you to control your inventory. Of course, problems can arise, and even a solid system can break down.

REASONS FOR POOR INVENTORY CONTROL

So what exactly causes poor inventory control?

To find the answer, it comes down to understanding that a loss in inventory control can stem from two different sides of your business.

It can either begin right at the beginning, during the actual inventory planning stage or nearer to the end, which is during the operations stage when your inventory is on its way to your stores.

1. MISCOMMUNICATION WHEN PLANNING YOUR INVENTORY

The planning stage of inventory control is all about knowing how much inventory you need to place on your shelf. You also have relative control of this side of your business since you know how much is going into your store and can thus order your inventory accordingly.

For example, you place three mugs on your shelf, and they're going to have three facings deep. That means you have nine mugs in total. Since a case pack contains 12 mugs, you also know you have three mugs in the storeroom as a backup. As soon as you sell a certain amount of mugs, you can then place an order for another case pack.

It all sounds straightforward. And it is. But what happens when you change the space allocations in your stores? While you'll still have control of your inventory, it will be poor a best. That's because you won't have the additional data required to stock your stores appropriately.

2. A BREAK DOWN IN YOUR SUPPLY CHAIN

While you have some control during the planning stage, you most certainly don't have control over the second part: the operations stage.

The operations side of inventory control revolves around your supply chain. And it doesn't take much for it to break down.

Considering that there are so many different moving parts in any given supply chain, there is always a chance of something going wrong. It could be something as big as a supply truck breaking down, which means your store doesn't reach your stores in time to sell. Or it could be as small as a merchandiser not interested in unpacking a few boxes.

CONSEQUENCES OF POOR INVENTORY CONTROL

ABANDONED SHOPPING BASKETS

A well-known store closing down is a consequence of poor inventory control. You only need to look at the news around Target Canada a few years ago to confirm that. Of course, such an event isn't a daily occurrence.

The more significant damage happens every single day: dropped baskets. Otherwise known as abandoned shopping baskets, it happens when a shopper walks into your store, looks for a product but can't find it, and so walks out of your store mid-shop. And it doesn't matter if it's just one item or a few they can't find.

As a result, whenever they go looking for the product they couldn't find at your store, they'll have it in the back of their mind that you probably don't stock it. That's even if you do.

OUT OF STOCKS AND OVERSTOCKED STORES

By not communicating when planning your inventory, there is a disconnect between the stock you want to arrive at your store and the stock that arrives. The consequences of this confusion should be obvious: you'll either not have enough stock in your stores or you'll be overstocked.

To fully understand the consequence of out of stocks, let's use the example of an average customer shopping in your store.

Imagine the item that pulls them into your store is a foot traffic generator, but all the other items in their basket are high profit. And your customer drops the basket because one or more products are out of stock. That's only a single shop, but you only need to consider the compounded impact on your profit margins.

On the other hand, in overstocking your stores, you're putting dead stock in your storeroom. Also known as obsolete inventory, that's the stock you can't sell. And since you've already paid full price for this stock, you'll end up losing (and wasting) your money. Plus, all of this dead stock is taking up valuable space that you could use for products that are selling and making you money.

HOW TO COMBAT POOR INVENTORY CONTROL

1. HAVE A BACKUP PLAN IN CASE YOUR SUPPLY CHAIN BREAKS

Considering that everything around your supply chain is mostly, if not all, out of your control, it's recommended that you have a backup plan in place.

It sounds like an obvious bit of advice. It is. Your more advanced retailers will undoubtedly have a robust supply chain that will include a backup plan if some part of it fails. But that doesn't mean that it is also not easily overlooked by other retailers, both large and small.

Regardless of how large or small you are, you must consider having a backup supplier.

As for the complexity of the plan, it can be simple. So long as it can help you where the supply chain breaks, it should be okay.

2. HAVE SPECIFIC CONTROL MEASURES IN PLACE WHEN PLANNING STOCK CONTROL

Before you begin planning what inventory to stock, it's necessary to ensure you have a way to track and measure.

For such a plan to work, it also needs to come from the top (Head Office) and filter down to your store level to implement it.

How do you ensure it will work as initially outlined? Simple: once the plan arrives at the store, it's the responsibility of the store manager to implement it. Once done, they will inform Head Office and provide evidence if need be.

3. ENSURE YOUR SPACE IS CONNECTED TO YOUR REPLENISHMENT ENGINE

Your supply chain must be spatially aware at all times. What that simply means is your replenishment engine needs to know exactly how much space is available on your shelf.

It's not the same as having your range connected to your space. In that case, it's focusing on your range that fills your drops. And so you send the planogram off to be implemented.

But what you haven't done is you haven't told your replenishment engine that the space allocations might have changed from one facing to three facings.

To correct it, you must increase your replenishment rate to the appropriate amount.

By doing that, you'll ensure that with any anticipated increase, you'll not only cover the initial stocking of the product but also ensure that your replenishment engine knows that more products are sitting on your shelf.

For inventory control, all your systems must be talking to each other.

LET DOTACTIV HELP YOU BRING YOU CATEGORY PLANS TO LIFE

Increase your revenue by between 5% and 30% by giving your products data-driven space allocations and applying consistent merchandising principles across your stores.

With our assortment optimization service, you'll get quick access to the expertise, software and process required to ensure you develop space and inventory-aware assortments, tailored to local shopper preferences.